The world of industrial pipe flanges is evolving rapidly, driven by advancements in technology, materials, and industry demands. Staying ahead of these trends is crucial for businesses looking to maintain competitive advantages and ensure the efficiency, safety, and reliability of their piping systems. This guide delves into the future trends shaping the landscape of industrial pipe flanges and what they mean for your projects.

1. Advanced Materials for Enhanced Performance

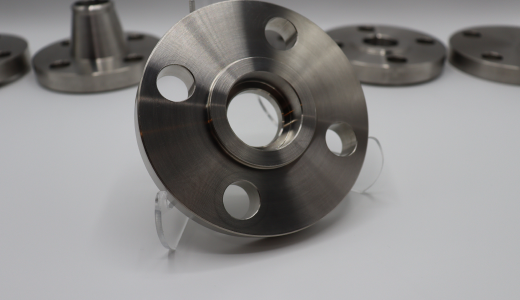

As industries push the boundaries of what their systems can handle, the demand for advanced materials in pipe flanges is on the rise. These materials offer improved durability, corrosion resistance, and temperature tolerance.

- High-Performance Alloys: Alloys such as Inconel, Hastelloy, and Monel are increasingly used in flanges to withstand extreme environments, including high-pressure and high-temperature applications.

- Composites: Composite materials, combining metals with non-metals, offer lightweight yet robust solutions for specific industrial needs, reducing overall system weight without compromising strength.

2. Digital Integration and Smart Flanges

The integration of digital technologies into industrial components is transforming how systems are monitored and maintained.

- IoT and Sensors: Smart flanges equipped with IoT sensors can provide real-time data on pressure, temperature, and potential leaks. This enables predictive maintenance, reducing downtime and extending the lifespan of the system.

- Digital Twins: Creating digital replicas of physical flanges allows engineers to simulate and analyze their performance under various conditions, leading to optimized designs and proactive issue resolution.

3. Sustainability and Eco-Friendly Solutions

With a growing emphasis on sustainability, the development of eco-friendly industrial flanges is gaining momentum.

- Recyclable Materials: Using recyclable materials for flange production not only reduces environmental impact but also meets regulatory requirements and enhances corporate sustainability profiles.

- Energy-Efficient Manufacturing: Advancements in manufacturing processes aim to reduce energy consumption and emissions during flange production, contributing to greener operations.

4. Customization and On Demand Manufacturing

The ability to customize flanges to specific project requirements is becoming more accessible and efficient with advancements in manufacturing technology.

- Additive Manufacturing (3D Printing): 3D printing technology allows for the rapid production of custom flanges with complex geometries, reducing lead times and material waste.

- Flexible Production Lines: Modern manufacturing facilities equipped with flexible production lines can quickly adapt to produce different flange types and sizes, meeting diverse customer demands.

5. Enhanced Standards and Compliance

As industrial processes become more sophisticated, the need for stringent standards and compliance grows.

- Global Standardization: Efforts to harmonize international standards (e.g., ASME, ISO) ensure flanges meet consistent quality and safety criteria, facilitating global trade and interoperability.

- Real-Time Compliance Monitoring: Digital tools enable real-time monitoring of flange manufacturing processes, ensuring adherence to standards and reducing the risk of non-compliance.

6. Focus on Reliability and Safety

Ensuring the reliability and safety of piping systems remains a top priority, driving innovations in flange design and testing.

- Advanced Testing Methods: Non-destructive testing (NDT) techniques, such as ultrasonic and radiographic testing, provide detailed insights into flange integrity without causing damage.

- Improved Sealing Technologies: Innovations in gasket materials and flange surface treatments enhance sealing capabilities, reducing the risk of leaks and failures.

Conclusion

The future of industrial pipe flanges is marked by significant advancements in materials, digital integration, sustainability, customization, standardization, and safety. Staying abreast of these trends is essential for businesses looking to optimize their piping systems and maintain a competitive edge. At [Your Company Name], we are committed to leveraging the latest technologies and industry trends to provide high-quality, reliable industrial pipe flanges. Contact us today to learn more about our innovative solutions and how they can benefit your projects. Visit: https://www.texasflange.com/